TELESCOPIC JOINT D & I, REPAIR & RE-CERTIFICATION

Location: Perth Date: 2019

Our client – Oil States Industries

A Telescopic Joint from one of the MODU’s currently drilling off the WA north west coast was recently received at WPF. Weighing in at over 34 tons, this 15,000 psi Telescopic Joint with a 60 ft stroke, was one of the largest ever seen at WPF.

WPF’s scope of work included:

- A full Dismantle

- Inspection – including visual, NDT, PMI, dimensional and hardness testing.

- Reporting with findings & recommended dispositions

- Repairs where necessary.

- Parts and seals replacement where necessary

- Replacement of damaged and re-coating of re-usable fasteners.

- Manufacture of additional auxiliary line clamps.

- Replacement of all hydraulic tubing and fittings.

- Inner barrel changeout

- Reassembly in accordance with OEM procedures and with an additional two new auxiliary line clamps.

- Function & pressure testing of hydraulic circuits and packers.

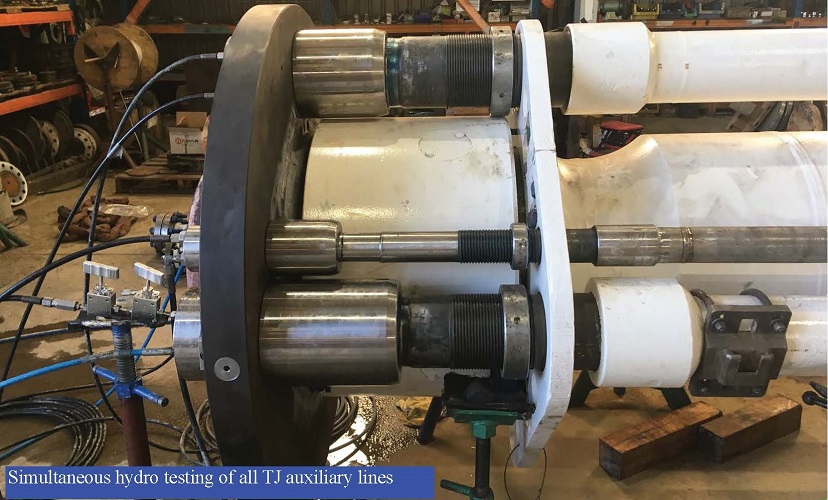

- Manufacture of a special test tool to allow testing of the auxiliary lines either individually or in combination.

- Pressure testing of all auxiliary lines.

- Recoating of TJ to subsea paint specification.

- UHP washing and sealing of hydraulic lines

- Installation of new protectors onto all main tube and auxiliary line ends.

- A full DROPS compliance survey prior to load out.

- QA documentation and traceability report

< Back to Projects