CONDUCTOR CASING / WELLHEAD WELDING

Location: Perth Date: March 2016

Our client – Oil States Industries

Three sets of recovered 30” Low Pressure Wellhead Housings and two sets of recovered 18 ¾” High Pressure Housings with adaptors were sent to WPF for replacement of the casing extension sections. All housings and casing extension joints were free issued.

WPF’s scope of work included:

- Qualify a suitable Submerged Arc welding procedure for joining the HP and LP wellheads to the casing material in compliance with the applicable specifications.

- Receipt free issue wellheads and new replacement casing extension sections.

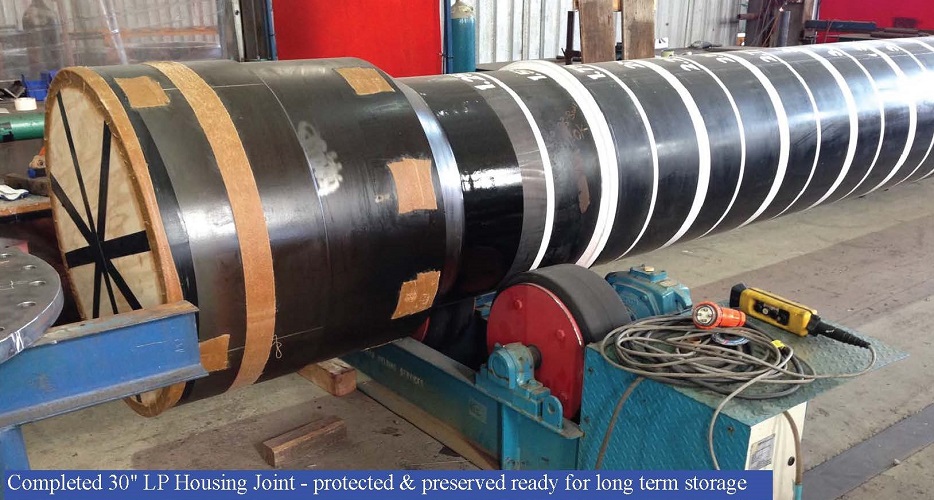

- Set up and weld the LP housings to 30” OD x 1.5” wall casing extensions.

- Remove the remnant welds and HAZ from the 18 ¾” HP housing adaptors and re-machine weld bevels.

- Set up and weld the HP housings to 20” OD x 1” wall casing extensions.

- Heat treat all welds in accordance with the weld procedure specifications.

- Grind flush all butt welds on OD and ID.

- Carry out NDT and hardness testing in accordance with client requirements.

- Paint bands and markings onto the HP and LP wellhead joints as per client requirements.

- Preserve wellhead joints for long term storage

- Protect and prepare joints for shipment.

- Compile and submit QA documentation.

< Back to Projects